OUR HARDNESS TESTERS & ACCESSORIES

NEWS

NEW Corporate Identity

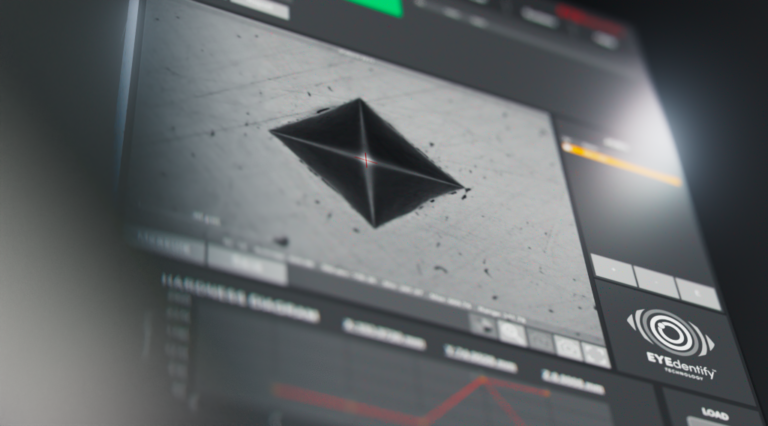

Introducing EYEdentify™

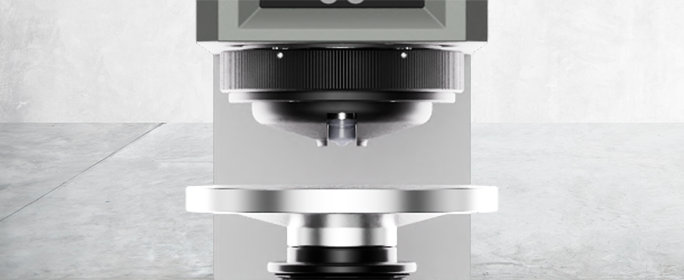

Hardness testing machines for metals

At GNEHM, we specialize in providing high quality hardness testers designed for accurate and reliable testing of metals. Our hardness testing machines support various standardized methods, including Rockwell, Vickers, Brinell and Knoop, ensuring compliance with international testing standards.

Our product range of hardness testers

Our product line includes three main types of hardness testers, each tailored to specific testing needs and material characteristics. All of our machines are designed with automation in mind, offering efficient and consistent results with minimal operator input. Learn more about our automatic hardness testing systems.

Specifically, our testers include:

- Rockwell Hardness Testers: ideal for testing metals with varying hardness levels, offering quick and direct readings.

- Vickers Hardness Testers: suitable for small or thin metal specimens, providing precise measurements. All our Vickers machines can also be used for Knoop hardness tests.

- Brinell Hardness Testers: best for testing metals with coarse structures or uneven surfaces.

In addition, we offer a range of consumables such as indenters and test blocks to support your hardness testing needs.

How our hardness testers are used

GNEHM hardness testers ensure material integrity across a wide range of applications. For example, Rockwell testing (ASTM E18, ISO 6508, JIS Z2245) is commonly used to check the durability of parts like gears and bearings. To assess coatings and thin materials in electronics, the Vickers method is often the best choice. It follows ASTM E92, ASTM E384, ISO 6507, and JIS Z2244 standards. Engineers typically assess heavy-duty components like castings and forgings using Brinell testing (ASTM E10, ISO 6506, JIS Z2243). Additionally, Knoop testing (ASTM E92, ASTM E384, ISO 4545, JIS Z2251) helps evaluate thin films in medical devices.

Overall, early detection of weak points across all methods helps prevent failures and reduce production costs.

The importance of metal hardness testing

Metal hardness testing is critical in determining the ability of a material to resist deformation, wear and tear. It ensures that metals meet the requirements for specific applications, maintaining safety, reliability and performance standards across various industries.

Where our testers make a difference

Our hardness testers are utilized across various industries for metal testing applications, including:

- Automotive: ensuring the durability of metal components.

- Aerospace: testing metal parts for structural integrity.

- Manufacturing: quality control of metal products.

- Research & Development: material analyses and development.

Why choose GNEHM hardness testing?

GNEHM hardness testers are indispensable tools in engineering and manufacturing, as they drive innovation while maintaining safety and performance.

- Accuracy: our testers deliver precise measurements, ensuring material reliability.

- Versatility: suitable for a wide range of metals and alloys.

- Compliance: adherence to international standards like ASTM, ISO and JIS.

- Support: comprehensive customer service and technical support.

Get in touch for expert hardness testing advice

Whether you’re looking to improve quality control, ensure compliance, or select the right hardness tester for your application, our experts are here to help. Discover how GNEHM’s metal hardness testing solutions can support your operations with precision and reliability.

Let’s find the right solution together.

OUR CUSTOMERS

* The logos displayed below are the sole property of their respective owners and are shown for reference purposes only. They do not imply any endorsement, partnership, or affiliation beyond what is explicitly stated.

|

|

|

||

|

|

|